Ports & Maritime

Keep ports and maritime vessels moving with 24/7 port-side access to critical items.

We transform existing on-site stores, or power stand-alone staffless mini warehouses with intelligent stock control, multi-point security and a click-and-collect web ordering system to ensure maintenance engineers and port services have the supplies they need to provide the best time-critical service when it's needed most.

Problems We Solve

Have you experienced project delays and reduced productivity by not having access to key products?

Ports

Not all port suppliers have a physical footprint or the space to store valuable products nearby, and where they are, it's often not in a controlled manner with secure 24/7 access, which can lead to service delays or increased costs.

Shipping

Planned or unplanned maintenance must be instant to keep the fleet operating to schedule. Without access to criticial items when needed crews may risk delays if critical parts cannot be delivered in time.

Remote Locations

Non-mainland ports don't always have parts to hand, so ordering can cause unwanted delays and increased shipping costs, with higher prices charged to deliver from mainland locations.

Fewer Delays

Increase productivity with access to critical items when you need them.

Hold a stock of key items on site with automated trigger levels for reordering to improve availability and reduce unwanted stockouts or unplanned delays waiting for deliveries to ports sites or maintenance crews.

Reduce Costs

Remove waiting costs, penalties and higher sourcing prices with planned inventory.

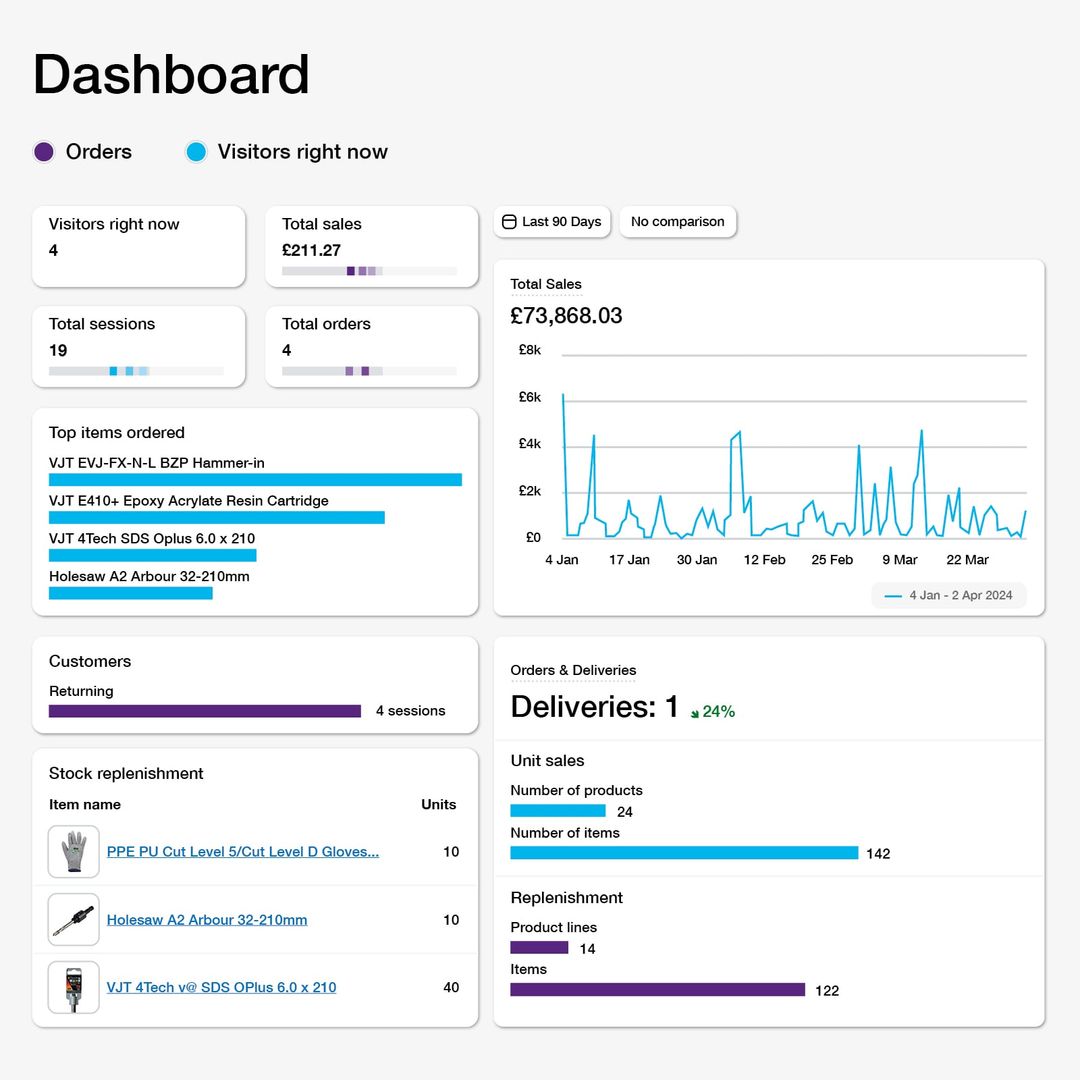

Real-time stock levels of critical parts, uniforms, PPE or maintenance products are viewable in a dashboard and positively impacts cash flow as it negates the need to pre-order stock in advance. Plus, with secure access and individual order tracking, it's easy to know who uses the products and it reduces loss and theft from busy locations.

Better Sustainability

Improve your carbon footprint with fewer deliveries to site.

Local teams can plan ahead with enough stock to last weeks at a time, and when replenishment is required, it is done using data insights to consolidate consignments for greater efficiency, thus reducing the number of individual deliveries to sites.

Case Studies

Dive deeper into real-world customer deployments of Opus. Discover how Opus is helping customers transform their sales and supply chain operations.

Speak to our team

If you would like to learn more about Opus in the ports and maritime industry, speak to our client success team who will be happy to discuss implementation and capabilities.